Developed in 1939, the Japanese type 99 gas mask was an improvement of the older type 95. The type 99 began to be issued in November of 1941 and would see service all over the Japanese empire. The type 99 gas mask consists of three primary components. The rubberized fabric mask, the filter hose, and the filter canister. The mask was made of a rubberized canvas material that creates an airtight barrier, as was the filter hose. The filter can was aluminum and made of several layers of activated charcoal and soda lime separated by wire mesh. A rubber plug was used to seal the bottom of the canister during fording and any time the mask might get wet to prevent water from entering the filter. A metal clamp was also provided to prevent water from entering through the hose. The filter attaches to the hose by means of a clamp and wing nut and the hose is permanently attached to the mask.

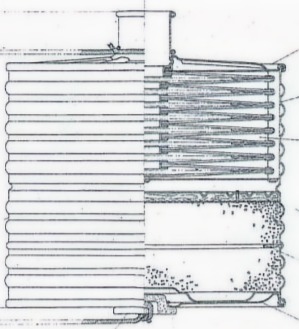

Filter diagram (left), rubber plug on bottom of filter (right)

The type 99’s eyepieces are removable for cleaning or replacement by unscrewing them

counterclockwise. The lenses themselves are a three-part construction consisting of two panes of glass with a celluloid disk sandwiched between them. The celluloid ensured that the mask would continue to stay air-tight even if a lens was damaged. Japanese gas masks are often encountered with what appears to be cracked lenses; however, this is due to the breakdown of the middle cellulose layer. Over time the cellulose begins to crystallize, and cracks begin to form. Generally, this begins at the edges of the lens and slowly works its way inward.

Although the type 95 mask served the Japanese army well, there were definite areas for improvement. The focus during the development of the type 99 was improving fit, visibility, weight reduction, and anti-fogging capability. The new type 99 mask would be shaped and molded to be more ergonomic, and the nose area was enlarged and widened. The nose was also strengthened by the addition of thicker material to provide more rigidity to the center section of the mask and improve airflow. The greater room and airflow in the nose section also served to make the mask more comfortable.

Visibility was improved by enlarging the lenses and molding the mask in a way that the lenses had a more forward-facing direction. This did reduce peripheral and downward vision to some degree, but greatly improved the soldier’s ability to aim and fire his rifle while wearing his mask. Ribbing was added to the eye lens rings to improve durability and provide a better grip for removal.

Weight reduction was accomplished by reducing the thickness of the mask’s material, this also aided in making the mask more flexible, allowing it to conform more easily to the contours of the face. The major element to weight reduction however was making the filter cannister smaller. The earlier type 95 gas masks had a filter life of approximately 100-120 hours. The type 99’s filter was reduced in size resulting in around 65 hours of usable service. This reduction in size of the filter made it shorter, and eliminated some air resistance, making it just a little easier to breathe.

Tissot tubes focus fresh air toward the center of the lens

The major improvement of the type 99 over the type 95 was its anti-fogging ability. Tubes, known as tissot tubes, serve to draw fresh air up and across the lenses to reduce fogging and condensation. These tubes were used in the type 95 and still exist in modern gas masks today. The type 99 remolded these to be more effective by focusing the airflow on the center of the lens.

An additional insert called a separator could be added to the mask in temperatures below 25 degrees Celsius (-13 F). This insert attached to the mouth area of the mask and created a seal that did not allow the exhaled breath to stay inside the mask. These changes greatly improved the masks’ anti-fogging ability in extreme cold, as was often encountered in places like Manchuria and the Aleutians.

Anti-fogging ability was also improved by using anti-fog lens inserts. Anti-fog inserts came in either a black plastic box or a small olive drab metal case. Made of cellulose, these thin plastic disks serve to keep condensation away from the inside surface of the lens during cold weather. To insert the anti-fog disk, unscrew the eyepiece of the mask and remove the lens assembly. Set the anti-fog disk into a recessed ring inside the eyepiece socket. Reinstall the eyepiece and snug it down. Due to age and corrosion, the eyepieces may not be removable or may be quite stubborn. Go slow and be careful if you try to remove yours.

Antifreeze liquid was also issued as a part of the gas mask kit. Below a certain temperature, the moisture from exhaled breath builds up and freezes the small rubber air exit valve in the closed position making it impossible to wear the mask. The liquid itself was a mixture of ethylene glycol and alcohol and supplied in either small metal flasks or black plastic cylinders. The flask has a black rubber stopper with a wire and cloth attached so that antifreeze can be swabbed on. The cylinders are used as droppers to place drops of antifreeze liquid onto the valve. The air exit valve is accessed by a hinged metal cover, this is another upgrade from the earlier type 95's screw-on cover.

Air exit valve and antifreeze flask

The type 99 gas mask and its accessories were carried in a green water-repellant canvas bag with either a metal snap button or a cloth tab and button for closure. The carry bag sling could be quickly shortened or lengthened using a stud mounted on the sling. The stud could be inserted into a cloth or leather tab on the side of the carry bag, shortening the sling. The inside of the carry bag is divided by a cloth partition, one side for the filter and the other for the mask.

The filter side has a cardboard insert that supports the filter when in use and provides a standoff distance between the air inlet at the bottom of the filter and the bottom of the carry bag. There are two pockets in the upper portion of the carry bag that contain the anti-fog inserts, a cleaning cloth, and a metal clamp for the air hose. A chemical decontamination kit and user manual were also issued and carried in the bottom of the bag.

The carry bag was worn in two positions, carry and ready. The carry position was for when you were on the move and did not expect to use it, but still needed to have it on you. The bag was slung from the right shoulder to the left hip. In the ready position, the bag was hung around the neck and the sling was shortened. Two cloth ties wrapped around the body and were tied to secure the bag to the chest. This position was used when there was a possibility of chemical weapons and the mask needed to be available at a moment’s notice. The ready position was also used when wearing the mask because it held the filter canister and provided access to the accessories.

Cardboard insert for filter support and upper bag pockets for accessories

Carry position (left), ready position (right)

Chemical decontamination kits were also issued as a standard component of the gas mask set. They consisted of chloramine T powder, and either a rubber or cotton-covered rubber bag. Chloramine T is a mild disinfectant that comes in the form of a white powder resembling baking soda and is mixed with water in the rubber bag to form a paste. This paste could be applied to equipment and skin to absorb and remove chemical contamination. Chloramine T is still used in medicine today to treat chemical burns. The powder comes in either olive drab cans, or black plastic containers resembling saltshakers.

The complete type 99 gas mask kit would include the mask, hose, filter, carry bag, decontamination kit, anti-fog lenses, antifreeze liquid, hose clamp, cleaning cloth, and user manual. Other items could be issued on an ‘as needed’ basis such as the cold weather separator, and chemical protective suits. A small package of litmus paper was also used for detecting chemical agents. The user manual covers various topics and includes instructions on donning and doffing the protective mask, types of chemical attacks, and mask care instructions. These manuals are particularly rare and not often encountered.

Variations of the type 99 that accept screw-in filters can also be found. These masks are often referred to as ‘civilian’ gas masks, but the Japanese military also used them. Other masks were developed specifically for civilians, including children, and there were even gas masks and other protective equipment designed for horses. The type 99 gas mask would continue to be manufactured and issued for the duration of the Second World War and see service throughout all theaters of Japanese conflict.

Type 99 gas mask manual

Many types of Japanese gas masks can be found in collections around the world and in varying degrees of condition. Most gas masks and their hoses have become hard and brittle over the decades due to the rubber losing its elasticity, and the lenses are often seen with what appear to be cracks, and degradation of the lenses' celluloid layer can range anywhere from absent, to completely crystallized. if you have one of these gas masks, its recommended to store them in a dry, cool place away from humidity and direct sunlight.

コメント